Automation For Boiler Blowdown Saving You

Water, Money, Chemical, Fuel, Time, and More.

What is a Boiler Blowdown?

Boiler blowdown is a process of removing impurities, such as dissolved solids and sludge, from the water within a boiler system.

In a boiler, water is heated to produce steam, and during this process, impurities can accumulate in the water. These impurities include dissolved minerals, salts, and other substances that can concentrate as water is boiled and steam is produced. Blowdown is the process of periodically releasing a portion of the boiler water to remove these impurities and prevent their concentration from reaching levels that could cause problems such as scale formation, corrosion, and reduced boiler efficiency. The blowdown is typically performed at the bottom of the boiler to remove the heavier, more concentrated impurities that settle there.

Proper boiler blowdown is essential for maintaining the efficiency and longevity of a boiler system. It helps prevent the buildup of scale, reduces the risk of corrosion, and ensures that the boiler operates at optimal conditions. The frequency and volume of blowdown depend on factors such as the boiler design, water quality, and the specific requirements of the system.

Why is an Automated Boiler preferable to a manual Boiler Blowdown? Automating a boiler blowdown is helpful for many reasons. Some of the more important reasons are:

- Consistency: Automated skimming systems can provide consistent and precise control over the skimming process. This ensures that the right amount of impurities and contaminants is consistently removed from the boiler water, leading to more stable and reliable boiler operation.

- Efficiency: Automated systems can be programmed to perform skimming at optimal intervals based on real-time data and water quality parameters. This can result in more efficient removal of impurities compared to manual methods, which may not be as consistently timed or controlled.

- Labor Savings: Automated skimming reduces the need for manual intervention, freeing up operators to focus on other critical tasks. This can lead to labor savings and a more efficient use of personnel resources.

- Timeliness: Automation allows skimming to be performed promptly in response to changing water quality conditions. This timeliness is crucial for preventing the buildup of contaminants that could otherwise lead to efficiency losses, corrosion, and other issues.

- Data Logging and Monitoring: Automated systems often come with built-in sensors and data logging capabilities. This allows operators to monitor the performance of the skimming process, track water quality trends, and make informed decisions based on historical data.

- Safety: Automation can enhance safety by minimizing the need for operators to physically interact with the boiler during the skimming process. This reduces the risk of accidents and exposure to hot or hazardous environments.

- Optimized Operation: Automated skimming systems can be integrated into a broader control system for the boiler, allowing for better coordination with other operational parameters. This integration can contribute to overall system optimization and improved efficiency.

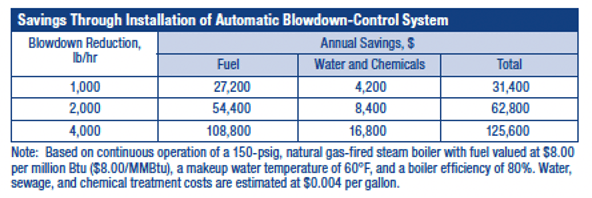

According to the US Department of Energy, the advantages of automatic blowdown-control system are; optimized surface blowdown rates, well maintained water chemistry, minimized blowdown, and reducing energy loss. They also recognize that this feature provides cost savings recognized from the significant reduction in the consumption, disposal, treatment, and heating of water. Below is a chart published by the USDOE on the savings available from installing an automatic blowdown-control system.