Creating Clean Loops and How to Maintain Them

Do you have a closed loop system? Make sure you are getting maximum efficiency and heat transfer with proper closed loop water treatment and regular testing.

What is Closed Loop Treatment?

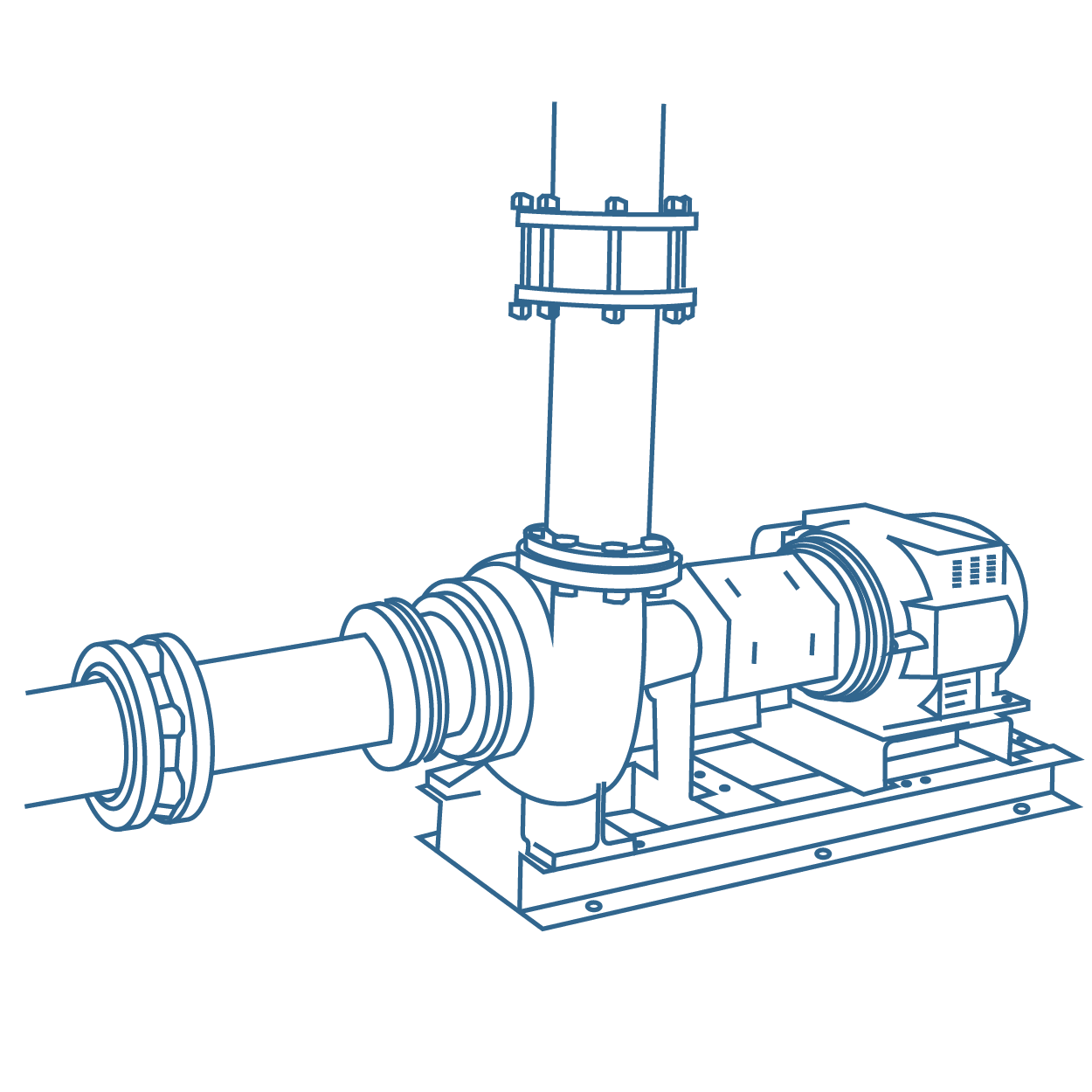

Closed loop systems are water systems engineered for heat transfer. Closed loop systems must be dosed with chemical additives to arrest corrosion, control microbial activity, and reduce scaling that can occur. Untreated, each of these will rob your systems of efficiency and raise operation costs.

What is water treatment for closed loops?

There is a myriad of chemical corrosion inhibition programs for closed loop systems. Correct product selection will be based on type of system, thermal loads, size, and any environmental factors that must be considered.

How often should I test my closed loop?

Closed loop systems are defined by AWT as any water recirculated system that is completely sealed and does not regularly, or by design, take on make-up water, no more than 5% per day.Tight closed loop systems (little or no water loss) can be treated successfully with quarterly water treatment checks. Systems with appreciable water loss may need to be checked more frequently.

Why is Closed Loop Treatment important?

Since water is always corrosive to metal, failure to treat a closed loop system will result in reduced heat transfer efficiency and reduced service life of your heat exchangers, pumps, and piping.

How does Closed Loop Treatment benefit my system overall?

Optimizing your heat transfer via excellent water treatment reduces your overall cost of operation by reducing fuel consumption, power usage, and by extending the service life of your capital equipment.

What are some signs that my closed loop is in trouble?

When system water is visibly rusty or turbid in appearance or gives off unusual odors, shows microbial activity, or experiences loaded filters, pay attention. Loss of heat transfer efficiency, plugging across heat exchangers and/or usual water temperatures, pinholes in piping, process contamination, water loss and repeated makeup are all potential warning signs of a bigger issue.

What can go wrong if I don’t have closed loop treatment?

If your closed loop system is associated with an HVAC system, closed loop system breakdown will result in failure of individual heat-source water pumps and possibly system-wide failure. Closed loop systems that fail when they are a part of a manufacturing process can result in the intermittent loss of operational time and eventual complete shutdown of process equipment while the closed loop system is serviced.

How do I come back from bad or nonexistent water treatment in my closed loop?

Closed loop systems that need to recover from a failure may need to be dosed with biocides, flushed, cleaned, filtered and/or retreated. A knowledgeable and reliable water treatment professional can assess and advise you on the best course of action.

Better Outcomes With Jaytech:

A Closed Loop System Recovery Story

Jaytech Water Solutions was recently asked to survey, and eventually was awarded the contract at, a large commercial property in the Saint Louis area. This building had a heat-recovery HVAC system where the closed loop system was incorrectly tested and insufficiently treated by the outgoing water treatment vendor for a long period of time. The closed loop system was loaded with corrosion byproducts (rust). This resulted in a presence of abundant microbial activity and inadequate filtration in place.

The plate-and-frame heat exchanger on the heat recovery system was so fouled with debris that the closed loop system was running extremely hot (above 100 degrees F). This caused the heat source water pumps all over the building to begin to fail. This resulted in the building having to shut down the gym and other connected amenities. Patrons at the connected upscale restaurant were complaining of hot party rooms and HVAC failures occurred throughout the living units. This building experienced several days’ worth of down time, incurred high labor and repair costs, and customer dissatisfaction.

This system needed flushing, acid cleaning, retreatment, improved filtration, and micro-biocide dosing in order to fully recover. The experts at Jaytech were able to return this application to service with as little down time as possible. Jaytech continues to support this customer by performing monthly loop tests and managing the water treatment supplements

Why should I trust Jaytech with my closed loop systems?

For over 45 years Jaytech has been a leader in our industry. We have been consulting on closed loop systems and water treatment plans to help our customers realize efficiency and longevity in their water systems. We have commissioned and recovered hundreds of systems during that time.

Jaytech is on the cutting edge of innovation in water treatment. In addition to inhibitors and biocides we also have unique filtration and heat transfer additives and proprietary glycol blended products.

Jaytech leads the water treatment industry with the most CWTs, the most highly qualified education for water treatment. There is no one more qualified to design a water treatment plan for you.

1. 45-year track record.

2. Innovative technology.

3. Jaytech offers more CWT specially qualified Reps.