Say Goodbye to Mold and Bacteria with Drip Pan Tabs

Say Goodbye to Mold and Bacteria with Drip Pan Tabs

Protect Your Service Warranty Period

Reduce Service Calls & Increase Customer Satisfaction.

Ask Us About Bulk Price Options:

Why are drip pan tabs important?

For Air Handler Units, drip pan tabs are essential:

- Preventing microbial growth: The drip pan of an air handler can collect moisture, which can create an ideal environment for the growth of bacteria, mold, and other microorganisms. These microorganisms can cause health problems, such as allergies and respiratory issues, for building occupants. Treating the drip pan with antimicrobial solutions can help prevent the growth of these microorganisms.

- Improving indoor air quality: Microbial growth in the drip pan can lead to the release of harmful particles into the air, which can affect the quality of indoor air. By treating the drip pan, you can help improve the indoor air quality and reduce the risk of health problems for occupants.

- Reducing maintenance costs: If the drip pan is not treated, it can become clogged with dirt and debris, leading to blockages in the drainage system. This can cause water to overflow and damage other parts of the air handling system. Treating the drip pan can help prevent blockages and reduce maintenance costs.

- Compliance with regulations: Many building codes and regulations require regular maintenance of air handling systems, including the treatment of drip pans. By treating the drip pan, you can ensure that your building is in compliance with these regulations.

In summary, air handler drip pan treatments are important for preventing microbial growth, improving indoor air quality, reducing maintenance costs, and complying with regulations.

How do drip pan tabs work?

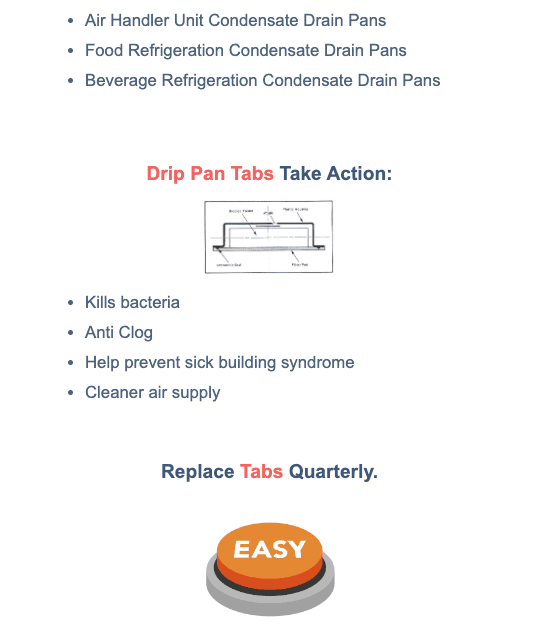

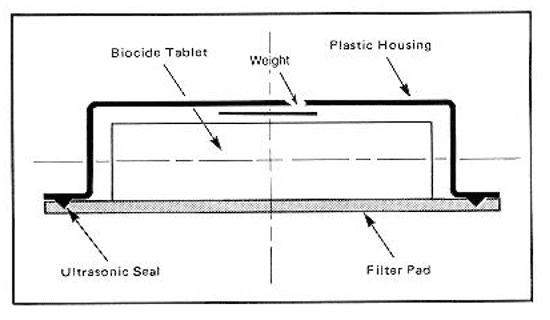

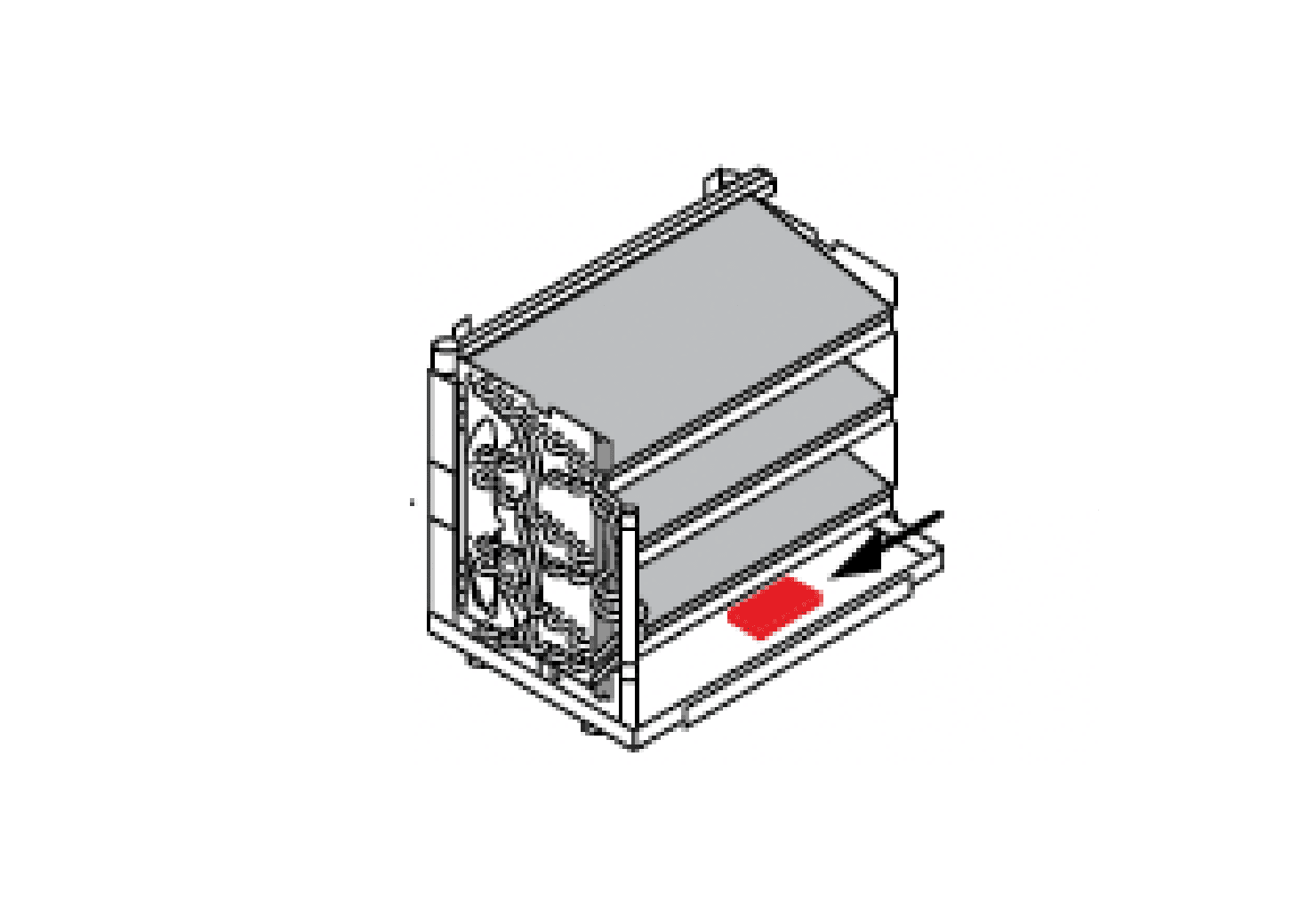

Drip pan tabs are used in air handlers to prevent the growth of bacteria and mold in the condensate drip pan. The drip pan is responsible for collecting the condensate that forms as warm air passes over a cold evaporator coil. If the drip pan becomes clogged with debris or overrun with bacteria and mold, it can lead to foul odors, decreased indoor air quality, and even damage to the air handling unit.

They are designed to slowly dissolve in the water in the drip pan, releasing a blend of chemicals that help to inhibit the growth of bacteria and mold. This helps to keep the drip pan clean and clear, preventing clogs and backups that can cause problems.

In addition to preventing the growth of microorganisms, some drip pan tabs for air handlers also contain corrosion inhibitors that help to protect the metal surfaces of the drip pan and air handling unit. This can help to extend the lifespan of the equipment and reduce maintenance costs over time.

To use drip pan tabs in an air handler, simply place them in the drip pan according to the manufacturer's instructions. Most tabs are designed to last for several months, but it's important to check them periodically to ensure that they are still working effectively.

Overall, drip pan tabs can be a useful tool for maintaining the cleanliness and functionality of air handlers. By using these tabs, you can help to prevent clogs and backups, improve indoor air quality, and extend the lifespan of your equipment.

Ask Us About Bulk Price Options:

Why do we need drip pan tabs for air handlers?

Drip pan tabs for air handlers are essential because the condensate drip pan in an air handling unit can quickly become a breeding ground for bacteria and mold. The warm and humid environment of the drip pan provides an ideal habitat for these microorganisms, which can grow and multiply rapidly if left unchecked.

If the drip pan becomes overrun with bacteria and mold, it can cause a number of problems. First and foremost, it can lead to foul odors that can permeate the building and negatively affect indoor air quality. In addition, the growth of microorganisms can lead to blockages in the drainage system, which can cause water damage to the air handling unit and the building itself.

Drip pan tabs are designed to prevent these problems by releasing a blend of chemicals that inhibit the growth of bacteria and mold in the drip pan. This helps to keep the drip pan clean and clear, preventing clogs and backups that can cause damage and unpleasant odors.

In addition to preventing the growth of microorganisms, some drip pan tabs for air handlers also contain corrosion inhibitors that help to protect the metal surfaces of the drip pan and air handling unit. This can help to extend the lifespan of the equipment and reduce maintenance costs over time.

Overall, drip pan tabs are an important tool for maintaining the cleanliness and functionality of air handling units. By using these tabs, you can prevent clogs and backups, improve indoor air quality, and extend the lifespan of your equipment.

What are some common applications for drip pan tablets?

Drip pan tablets can be used in most applications where small amounts of water can collect. Other than air handlers you can use these tablets in essentially any type of refrigeration unit including chilled display cases, refrigerated vending machines, beverage and grocery reach-in coolers, and cold storage walk-ins. Other HVAC applications include fan-coil units, ceiling units and roof top units.

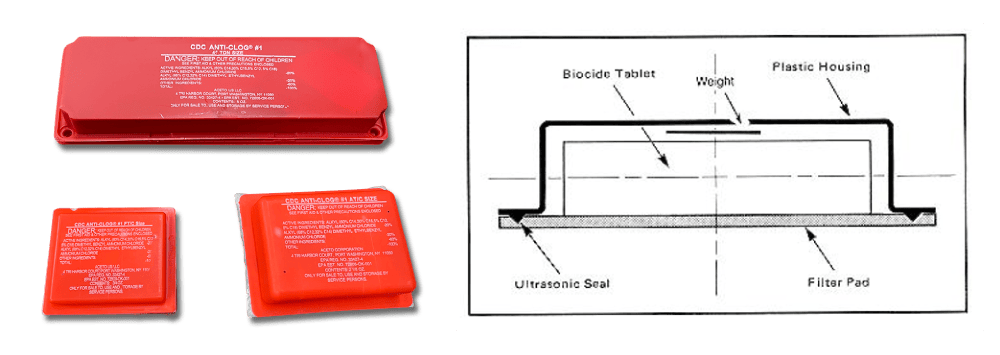

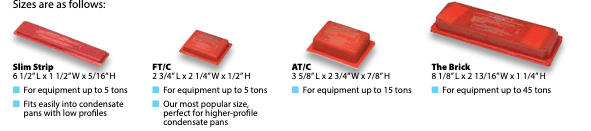

Drip pan tablets also come in a variety of sizes to suit the equipment pan size:

To learn more about how Drip Pan Tablets can help your system stay on track, talk with an expert today: