Chemical Delivery Systems,

Safely and Effectively Deliver Your Chemicals.

What is chemical feed equipment?

Whether your system requires a basic or complex water treatment plan, somehow you need a reliable way to monitor, adjust, and deliver your chemistries to your system at the accurate dosage continually. There are several types of equipment that can make up your water treatment chemical delivery system. The most common are:

- Bypass & feed board

- Chemical feed pumps

- Controllers

- Containment vessel

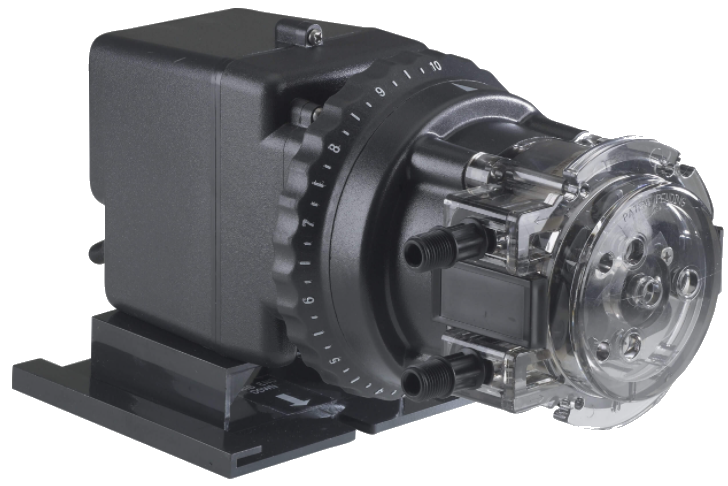

- Chemical metering pump

- Remote Monitoring

- Tanks

- Vessel - Chemical containment vessels are a necessary item to keep your mechanical room safe and clean. Containment vessels are double-walled for safety. They serve as a location for safety documents. They are the preferred place to mount your chemical pumps and they can be sized to hold enough chemical inventory to carry you between service visits.

- Pump - Chemical pumps come in many designs, costs and sizes. Each chemical has it’s own properties and feed rates, so the chemical metering pumps must be sized correctly and designed/constructed to deliver the chemical in question. Incorrect pumps can lead to immediate program failure. Therefore, it is key to work with your water treatment specialist to choose the correct pump for your application. Additionally, just like the tires on your car, chemical metering pumps have parts that need to be serviced and replaced at regular intervals.

- Board - Cooling towers require various probes and automation to control water quality in these dynamic heat transfer systems. The feed board can serve as a single point for all injectors, probes and automation in one convenient point for servicing. Steam boilers will need upgraded injectors due to high temperatures and pressures.

- Controller - The controller acts as an extra regulatory and monitoring component allowing you to automate and better monitor your chemical delivery. The controller is the brains of the operation. It receives input from water meters, flow switches, probes, etc. and electrifies chemical pumps in order to carry out the water treatment program as implemented by your water treatment professional.

What types of equipment do I need for my Closed Loop System?

Closed loops are the most simple water treatment applications. Due to the fact that water is not lost in these systems, only the simplest equipment is required. Most of the time, a filtration unit will be sufficient as the filtration unit doubles as a chemical pot-feeder. If the filtration unit is sized appropriately, the vessel will be large enough to deliver effective doses of required chemistries, whether they are liquids or solids.

What types of delivery equipment do I need for my Cooling Tower System?

Cooling towers are more dynamic than closed loops. Chemistries are usually liquids. For safety and cleanliness reasons, Jaytech recommends double-walled containment vessels for all liquid chemistries, appropriate chemical pumps for each chemistry, and a chemical feed board which includes the necessary automation. This will allow your Jaytech service representative to have safe, clean, and easy access to all points of interest for your chemical delivery system.

What types of delivery equipment do I need for my Steam Boiler System?

Steam boilers are similar to cooling tower set ups. Each chemical needs a containment vessel, appropriate chemical pump and automation. The key here is the elevated temperatures and pressures of these water systems require upgraded construction materials. Instead of a bypass, chemicals must be fed directly to a feed water tank or other preferred area of the steam system.

How do I know when it’s time to update my equipment? (How long do they last)

Chemical pumps need to be rebuilt on average every two years. If you have a 3 or 4 pump chemical program, that means you need to plan on rebuilding 1 or 2 pumps a year as routine maintenance.