The Most Important Step for Your New Cooling Tower.

The Most Important Step for Your New Cooling Tower.

Passivation is a very important process that every cooling tower needs before it is put into service. We receive a lot of questions about cooling tower passivation and how it works. Jaytech’s Technical Director Nate Woodrum is here to answer your Passivation questions. If you have questions that are not answered here, click the button at the bottom or leave us a comment..

What is cooling tower passivation?

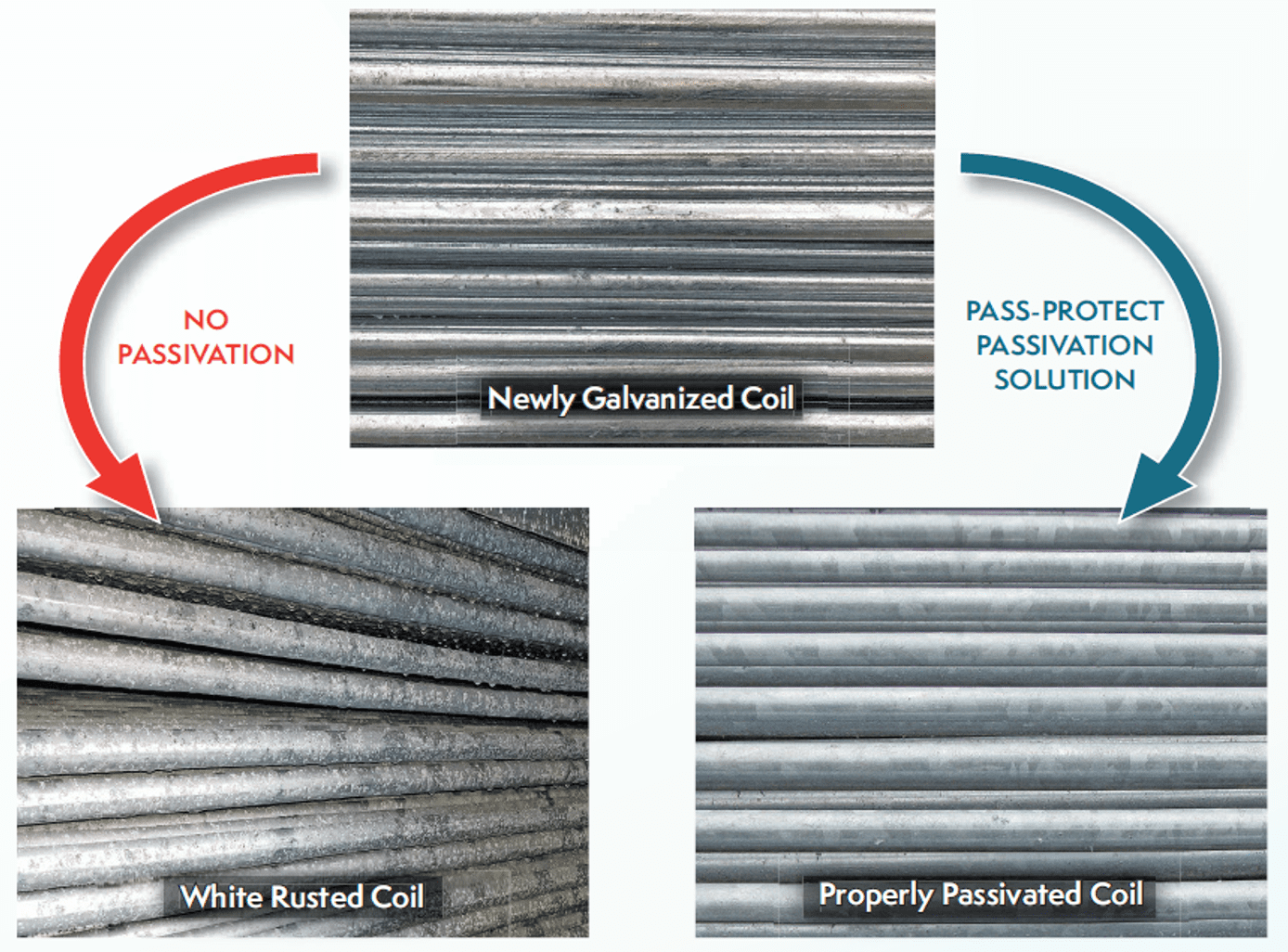

Let’s get right to the point. Cooling Tower Passivation is a chemical treatment process by which galvanized components are conditioned to produce a tenacious layer of metal surface. The new surface is resistant to white-rust corrosion under most cooling tower conditions.

Why is cooling tower passivation important?

Failure to complete the cooling tower passivation process as recommended results in early failure of heat transfer surfaces and reduced service life of your cooling tower. Based on water conditions at your site, it may also be necessary to conduct cooling tower passivation at regular intervals as the years pass.

How long does cooling tower passivation take to complete?

Under normal conditions the cooling tower passivation process will take eight to twelve weeks. After that time period, normal cooling tower operation and cooling tower water treatment can resume.

How do I properly execute cooling tower passivation?

The water treatment experts at Jaytech are trained and experienced to guide you through a successful cooling tower passivation. Contact a Jaytech water treatment expert a minimum of one month prior to startup of your cooling tower to ensure you have the correct automation and chemicals onsite for a successful cooling tower passivation. If the cooling tower has already been put into service without passivation, it is critical to get the process started as soon as possible. However, it is important to note, performing passivation after a cooling tower is in service may very well be too late.

What are some of the warning signs that my cooling tower was not properly passivated?

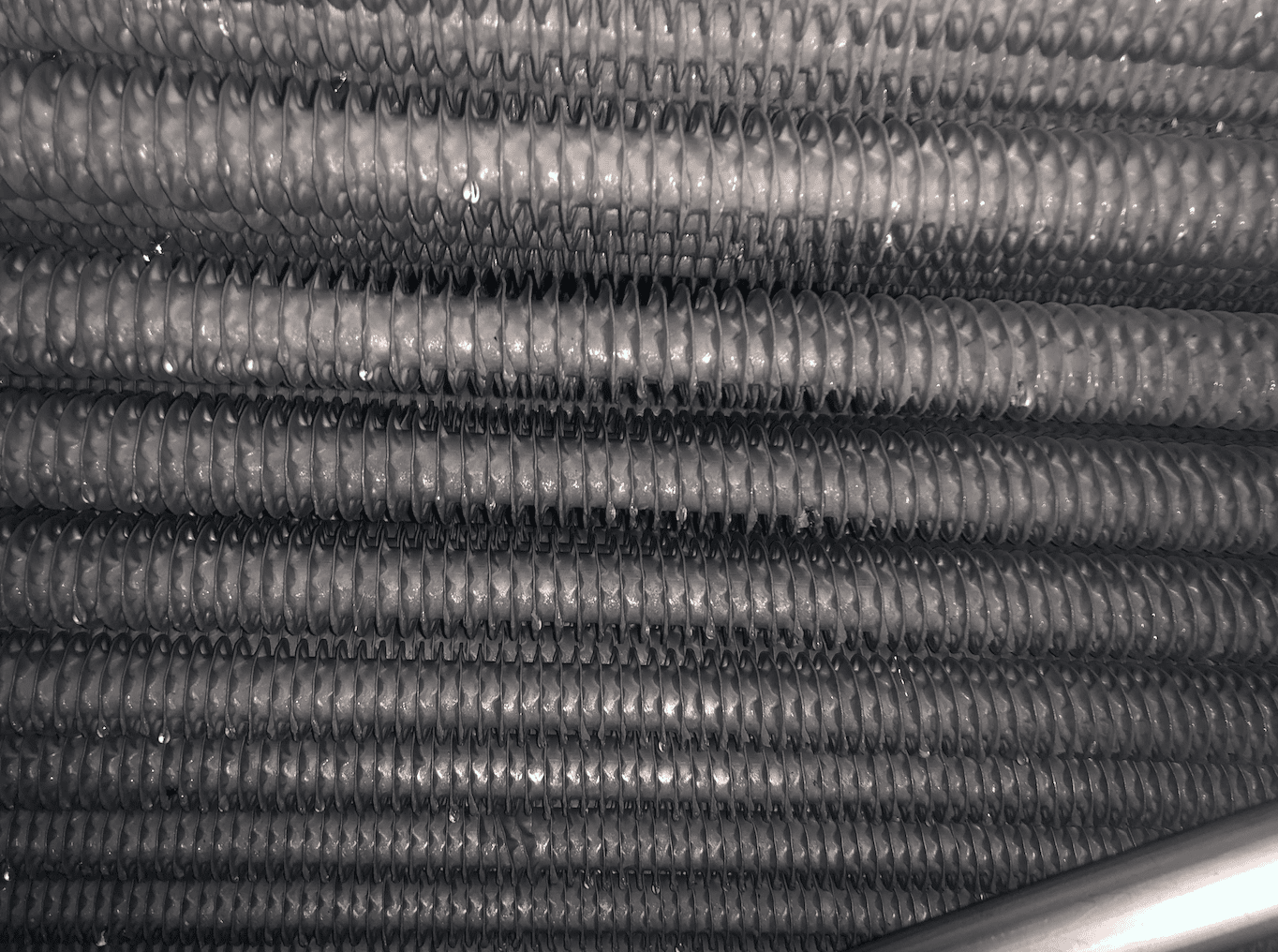

“White rust” is the corrosion by-product of galvanized components. White rust is often waxy in appearance and texture and is easily spotted on corroding galvanized surfaces.

The white rust observed in this cooling tower was on an evaporative ammonia condenser. White rust developed on this cooling tower after only 72 hours as the cooling tower was operating under a full heat load and followed none of the recommended water treatment procedures.

What do I do if my cooling tower was not properly passivated?

Cooling tower passivation procedures can be started late to mitigate further damage to your capital equipment.

Why should I trust Jaytech with my cooling tower passivation?

For over 45 years Jaytech has been a leader in our industry. We have been consulting on passivation and water treatment plans to help our customers realize efficiency and longevity in their water systems.

Jaytech is the official EVAPCO partner in the Midwest. EVAPCO is one of the most commercially used providers of galvanized towers and fluid coolers and they trust Jaytech to handle all their towers throughout our region.

Jaytech leads the water treatment industry with the most CWTs, the most highly qualified education for water treatment. There is no one more qualified to design a water treatment plan for you.

1. 45-year track record.

2. Official EVAPCO partners in the Midwest

3. Jaytech offers more CWT specially qualified Reps.