Get inside your pipes without getting inside your pipes

What are corrosion coupons?

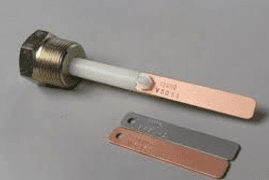

Corrosion coupons are small metal samples or strips that are used to monitor and assess the corrosion rates and types of corrosion occurring in a water treatment system. These coupons are typically made of the same material as the equipment or pipelines being monitored, such as carbon steel, stainless steel, or copper.

The coupons are designed to be representative of the metal surfaces in the system and are exposed to the same water conditions as the rest of the equipment. They are usually installed in specific locations within the system where corrosion is likely to occur, such as in pipelines, heat exchangers, or tanks.

How do corrosion coupons work?

Corrosion coupons work by allowing the water to come into direct contact with the metal surface over a specified period of time, usually several weeks or months. During this exposure period, the coupons undergo the same corrosion processes as the rest of the system. The rate and type of corrosion can be evaluated by measuring the weight loss or examining the physical appearance of the coupon after the exposure period.

By regularly monitoring and analyzing the corrosion coupons, water treatment professionals can assess the effectiveness of corrosion inhibitors, evaluate the impact of water chemistry changes, and identify potential corrosion issues before they cause significant damage to the equipment. This information helps in developing effective corrosion control strategies and optimizing water treatment programs.

Overall, corrosion coupons serve as a valuable tool in assessing and managing corrosion in industrial water treatment systems, providing important insights into the system's corrosion rates and helping to prevent costly equipment failures.

How often should corrosion coupons be tested?

Corrosion coupons should be tested every 90 days or once per quarter. The frequency of testing corrosion coupons depends on various factors, including the specific water treatment system, the severity of corrosion risks, and the objectives of the monitoring program. Generally, it is recommended to test corrosion coupons at regular intervals to ensure timely detection of any changes in corrosion rates or trends. Here are some considerations:

- Industry Standards and Guidelines: Some industries have established guidelines or regulations specifying the frequency of corrosion coupon testing. For example, in the oil and gas industry, standards such as NACE SP0775 recommend monthly or quarterly testing, while other industries may have different recommendations.

- System Conditions: The complexity and size of the water treatment system, as well as the nature of the water chemistry, can influence the testing frequency. Systems with higher corrosion risks or those dealing with aggressive water conditions may require more frequent testing.

- Equipment and Material Characteristics: The type of equipment, materials used, and their susceptibility to corrosion can impact the testing frequency. For instance, systems with mixed metals or alloys may require more frequent monitoring to evaluate galvanic corrosion.

- Historical Data and Trends: Initial testing can provide a baseline for corrosion rates. Based on historical data, trends in corrosion rates can be observed, and the frequency of testing can be adjusted accordingly. If significant changes are detected, more frequent testing may be necessary to identify the cause and implement appropriate measures.

- Water Treatment Program Changes: If modifications are made to the water treatment program, such as changes in corrosion inhibitors, biocides, or water chemistry parameters, it is advisable to conduct more frequent testing initially to assess the impact of these changes on corrosion rates.

It is important to consult with corrosion experts or professionals within your organization to determine the most suitable testing frequency for corrosion coupons based on the specific conditions and goals of your water treatment system. Regular monitoring and analysis of corrosion coupons will help ensure effective corrosion control and timely identification of any issues.

What are the benefits of utilizing corrosion coupons?

Using corrosion coupons in industrial water treatment systems offers several benefits. Here are some key advantages:

- Corrosion Rate Monitoring: Corrosion coupons provide a direct and quantitative measure of corrosion rates in the system. By periodically analyzing the weight loss or physical appearance of the coupons, it is possible to determine the rate at which corrosion is occurring. This information helps in assessing the effectiveness of corrosion control measures and identifying potential corrosion issues early on.

- Identification of Corrosion Types: Corrosion coupons can help identify the types of corrosion taking place within the system. Different corrosion mechanisms, such as general corrosion, pitting, or localized corrosion, can be detected and evaluated through the examination of the coupon surfaces. This knowledge is crucial for understanding the nature of the corrosion problem and developing appropriate mitigation strategies.

- Evaluation of Corrosion Inhibitors: Corrosion inhibitors are commonly used in water treatment systems to reduce corrosion rates. Corrosion coupons serve as a valuable tool for assessing the performance of these inhibitors. By comparing corrosion rates with and without the inhibitor, the effectiveness of the chemical treatment can be evaluated. This allows for adjustments in the dosage or selection of alternative inhibitors if necessary.

- Optimization of Water Treatment Programs: Corrosion coupons provide data that helps optimize water treatment programs. By monitoring the corrosion rates over time, water treatment professionals can assess the impact of changes in water chemistry, operating conditions, or treatment protocols on corrosion. This information aids in refining the water treatment program to achieve optimal corrosion control and cost-efficiency.

- Early Detection of Corrosion Issues: Regular monitoring of corrosion coupons enables the early detection of corrosion problems before they result in significant equipment failures or operational disruptions. By identifying changes in corrosion rates or trends, prompt actions can be taken to investigate the root causes and implement appropriate corrective measures. This proactive approach helps prevent costly repairs, downtime, and potential safety hazards.

- Compliance with Regulations and Standards: In certain industries, corrosion monitoring is mandated by regulations or industry standards to ensure the integrity and safety of equipment. The use of corrosion coupons helps demonstrate compliance with these requirements and provides a documented record of corrosion control efforts.

In summary, corrosion coupons play a vital role in monitoring corrosion rates, identifying corrosion types, evaluating corrosion inhibitors, optimizing water treatment programs, detecting issues early on, and meeting regulatory obligations. By utilizing corrosion coupons, industrial water treatment companies can effectively manage corrosion, extend equipment lifespan, and minimize operational risks.

Are corrosion coupons expensive?

The cost of corrosion coupons can vary depending on several factors, including the material used, size, quantity, and supplier. While the initial investment may be required to purchase the coupons and associated equipment, the overall cost of corrosion coupons is generally considered reasonable in relation to the valuable information they provide and the potential cost savings they enable.

Here are some considerations regarding the cost of corrosion coupons:

- Material: The cost of corrosion coupons can vary based on the material chosen. Different metals or alloys have different price points. Common materials used for corrosion coupons include carbon steel, stainless steel, copper, and various alloys.

- Size and Quantity: The size and quantity of corrosion coupons required for monitoring can impact the overall cost. Larger coupons or a higher quantity of coupons may increase the expense. However, the selection of appropriate coupon size and quantity should be based on system requirements and the level of accuracy desired.

- Installation and Retrieval: Corrosion coupons typically require some installation and retrieval procedures, which may involve additional costs such as labor, tools, and equipment. These costs should be factored in when considering the overall expense of using corrosion coupons.

- Frequency of Testing: The frequency of corrosion coupon testing can affect the total cost. More frequent testing may require a larger number of coupons and potentially increase operational expenses. Balancing the testing frequency with the importance of corrosion monitoring can help manage costs effectively.

- Long-Term Cost Benefits: While there are upfront costs associated with corrosion coupons, their use can help prevent costly equipment failures, mitigate corrosion-related damages, and optimize water treatment programs. The long-term cost savings achieved through effective corrosion control and extended equipment lifespan often outweigh the initial investment.

It is important to consider the cost of corrosion coupons in the context of the overall benefits they provide, including improved equipment reliability, reduced downtime, and optimized maintenance and operational costs.

If you would like to learn more about the overall cost to invest in corrosion coupons as a supplement to your water treatment program, click the button below and talk with an expert today!

What is the process like to add corrosion coupons to my system(s)?

Adding corrosion coupons to your water treatment system involves several steps. Here is a general overview of the process:

- Determine Monitoring Locations: Identify the key locations within your system where corrosion monitoring is essential. These locations should be representative of the areas prone to corrosion or where corrosion issues are likely to occur. Consider factors such as flow rate, temperature, and different metallurgies present in the system.

- Select Corrosion Coupon Material: Choose the appropriate corrosion coupon material that matches the metal surfaces in your system. The material should be compatible with the water chemistry and the specific corrosion mechanisms you want to monitor.

- Prepare and Install Coupons: Prepare the corrosion coupons according to the manufacturer's instructions. This may involve cleaning, surface preparation, and marking the coupons for identification. Install the coupons at the designated monitoring locations within the system. Secure the coupons in a way that ensures they are exposed to the same water conditions as the surrounding equipment.

- Document Installation Details: Maintain accurate records of the installation process, including the date, location, and any relevant information such as water chemistry parameters, coupon orientation, or specific conditions at the installation site. This documentation will be valuable for future reference and analysis.

- Exposure Period: Allow the corrosion coupons to remain in place and exposed to the system water for a predetermined period. The exposure period can vary based on the monitoring objectives, industry standards, or system-specific considerations. Typically, it ranges from a few weeks to several months.

- Retrieval and Inspection: Once the exposure period is complete, carefully retrieve the corrosion coupons from their installation locations. Take measures to minimize any potential interference with the surrounding equipment. Handle the coupons with care to avoid contamination or damage.

- Cleaning and Analysis: Clean the retrieved corrosion coupons to remove any scale, deposits, or surface contaminants. Follow the recommended cleaning procedures provided by the manufacturer. After cleaning, the coupons are ready for analysis. This may involve weighing the coupons to determine weight loss or conducting visual inspections to assess surface appearance and identify corrosion types.

- Interpretation and Reporting: Analyze the data obtained from the corrosion coupons and interpret the results. Compare the corrosion rates, types, and trends with previous monitoring periods or relevant benchmarks. Document the findings in a report that includes recommendations for corrosion control measures or adjustments to the water treatment program if necessary.

- Repeat the Process: Corrosion coupon monitoring is an ongoing process. Repeat the cycle by reinstalling new corrosion coupons at the monitoring locations to continue monitoring and evaluating the effectiveness of corrosion control strategies over time.

Why should I trust Jaytech with my Corrosion Coupons?

For over 45 years Jaytech has been a leader in our industry. We have been consulting on water treatment plans to help our customers realize efficiency and longevity in their water systems. We have commissioned and recovered hundreds of systems during that time.

Jaytech is on the cutting edge of innovation in water treatment. Our wide variety of product offerings lends itself to giving our customers a personalized custom water treatment plan like no other water treatment company can. We have created customizable blends of traditional chemicals, ultra concentrates, and solid chemistries. Coupled with our line of complementary products and our local hands-on approach, Jaytech has earned a reputation as a trusted partner in water treatment.

Jaytech leads the water treatment industry with CWTs, the most highly qualified education for water treatment. There is no one more qualified to design a water treatment plan for you.

1. 45-year track record.

2. Extensive customizable water treatment chemicals and complimentary products.

3. Jaytech offers more CWT specially qualified Reps.