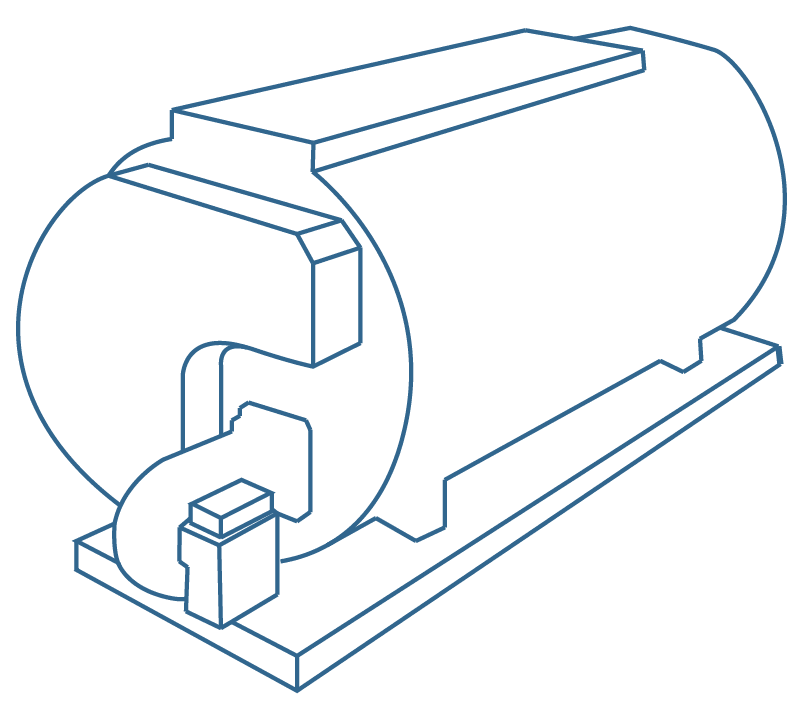

Boiler Inspection 101

Regular and thorough boiler inspections allow for early detection of issues, and timely maintenance and repairs. In turn, this helps prevent more costly breakdowns and extends the life of the boiler. Compliance with regulatory standards and adherence to manufacturer guidelines during inspections are fundamental to maintaining a safe and reliable steam boiler operation.

Why do I need a boiler inspection?

Performing a steam boiler inspection is crucial to ensure the safety, efficiency, and longevity of the boiler. Regular inspections help identify and address potential issues such as corrosion, leaks, and wear in critical components like the pressure vessel, burner assembly, and piping. Ensuring the proper functioning of safety devices, controls, and water level systems is essential for preventing hazardous conditions such as low water levels or excessive pressure.

A boiler inspection's purpose is to safeguard property and ensure the well-being of individuals working with or in proximity to boilers and pressure vessels. It is generally a state-regulated activity. Operating a boiler or pressure vessel (for example: Missouri) without a valid state inspection certificate could be considered a misdemeanor depending on the state in which your boiler is operating.

Guidance for pressure vessel operators in Missouri is provided by the Missouri Department of Public Safety, as outlined in 11 CSR 40-2. It's important to note that regulations may differ if your boiler is located in another state.

Since November 12, 1986, it has been mandatory for boilers, hot water heaters, and pressure vessels to adhere to the American Society of Mechanical Engineers (ASME) Boiler & Pressure Vessel Codes and be registered with the National Board of Boiler and Pressure Vessel Inspectors. Some exemptions apply based on size and facility type.

Who should perform my boiler inspection?

Boiler inspections are typically conducted by qualified and authorized professionals who have the knowledge and expertise to assess the safety and compliance of boiler systems. The specific requirements for inspectors may vary by jurisdiction, but generally, the following individuals or entities are involved in boiler inspections:

- Licensed Boiler Inspectors: Many jurisdictions require inspections to be carried out by licensed boiler inspectors. These individuals often have specialized training and certifications to assess the safety and functionality of boilers.

- Third-Party Inspection Agencies: In some cases, third-party inspection agencies may be contracted to perform boiler inspections. These agencies often have certified inspectors who are independent of the boiler's owner or operator, ensuring an unbiased evaluation.

- Authorized Inspectors from Regulatory Bodies: Regulatory bodies or government agencies responsible for boiler safety may employ inspectors who are authorized to conduct inspections and enforce compliance with relevant codes and regulations.

- Qualified Service Technicians: Depending on the type and size of the boiler, manufacturers or service companies may employ qualified technicians who can perform routine inspections and maintenance. However, for certain inspections, especially those required for compliance with regulatory standards, a licensed inspector may still be necessary.

Typically, your water treatment professional will also want to conduct a parallel inspection of the water side of a boiler and document any ongoing issues or improvements in the condition of the heat transfer surfaces.

It's crucial to check with the local regulatory authorities to understand the specific requirements for boiler inspections in your jurisdiction. They can provide guidance on who is authorized to perform inspections and what qualifications or certifications they should possess. Regular inspections are essential for maintaining the safety and efficiency of boiler systems.

How long does a boiler inspection take?

The duration of a boiler inspection can vary based on several factors, including the type and size of the boiler, its complexity, and the specific inspection requirements. In general, a routine inspection for a standard residential or commercial boiler might take a few hours. This involves a thorough examination of various components, checking for safety measures, and ensuring compliance with relevant codes and standards.

For larger industrial boilers or those in complex facilities, inspections may take longer and require more personnel. Some inspections might also involve additional tests, such as non-destructive testing, which can add to the overall time.

It's essential to follow the guidelines provided by regulatory authorities and adhere to any specific requirements outlined for the inspection. Additionally, regular maintenance and prompt addressing of any issues identified during inspections can contribute to the efficiency and safety of the boiler system.

How often do I need to perform a boiler inspection?

The frequency of boiler inspections can vary based on factors such as the type of boiler, its usage, and local regulations. In general, though, boilers should undergo regular inspections to ensure their safety, efficiency, and compliance with relevant codes. Here are some common guidelines:

1. Annual Inspections: Many jurisdictions and industry standards recommend annual inspections for boilers. This is standard practice for residential and commercial boilers to identify and address potential issues promptly.

2. High-Pressure Boilers: High-pressure boilers, often found in industrial settings, may require more frequent inspections, possibly every six months or even more frequently, depending on their usage and local regulations.

3. Boilers in Hazardous Environments: Boilers operating in hazardous environments, such as those in chemical plants or refineries, may require more frequent inspections due to the elevated risks associated with their operation.

4. New Installations: A new boiler installation typically requires an initial inspection to ensure compliance with construction and safety codes.

5. Special Circumstances: Certain events, such as major repairs or modifications to the boiler, changes in operating conditions, or safety incidents, may trigger the need for additional inspections.

Always consult with local authorities and adhere to relevant codes and regulations to determine the specific inspection requirements for your boiler. Additionally, manufacturers often provide recommendations for inspection intervals in the boiler's manual, and following these guidelines can help maintain optimal performance and safety. Regular inspections, combined with routine maintenance, contribute to the longevity and efficiency of the boiler system.

What items should I be looking for on a boiler inspection?

A thorough boiler inspection involves examining various components to ensure the safe and efficient operation of the system. While the specific checklist may vary depending on the type of boiler, its size, and local regulations, here are some common items to look for during a boiler inspection:

| Common rust and calcite deposits reduce efficiency. | Mineral scale deposits reduce efficiency. |

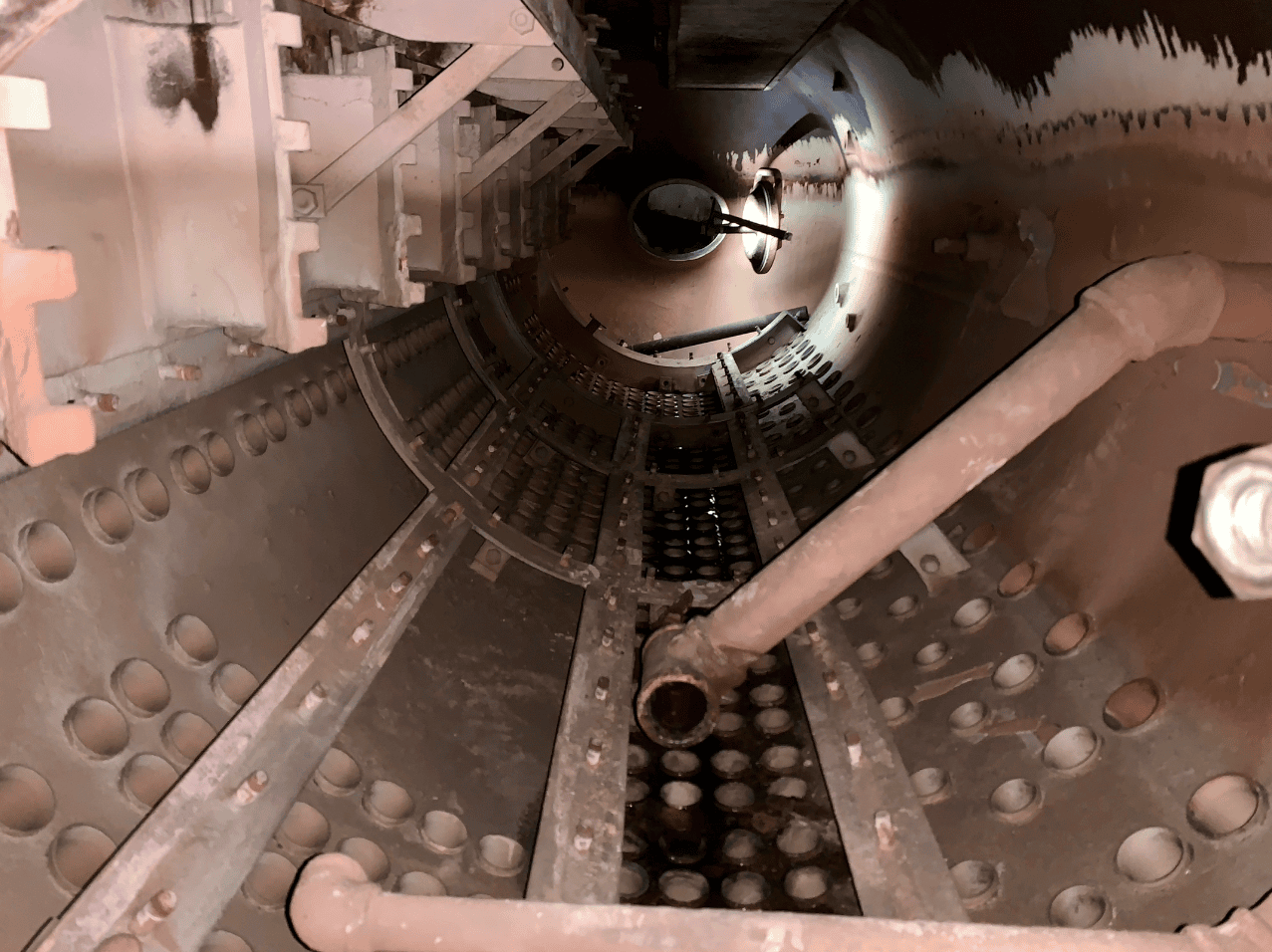

Healthy boiler tubes.

1. Pressure Vessel: Check the integrity of the boiler's pressure vessel for any signs of corrosion, leaks, or structural damage.

2. Boiler Controls: Inspect all control devices, including safety valves, pressure switches, and temperature controls, to ensure they are functioning correctly. 3. Burner Assembly:Examine the burner assembly for proper ignition, flame stability, and efficient combustion. Clean the burner and inspect for any signs of wear or damage. 4. Combustion Chamber:Check the combustion chamber for any debris, soot, or corrosion. Ensure proper flame patterns and combustion. 5. Flue and Venting: Inspect the flue and venting system for blockages, corrosion, or leaks. Verify that the draft is sufficient for proper combustion. 6. Water Level Controls: Test and calibrate water level controls to prevent low water conditions, which can lead to boiler damage.

7. Piping and Fittings: Examine all piping and fittings for leaks, corrosion, or signs of wear. Check for proper insulation where necessary. | 8. Safety Devices: Verify the operation of safety devices, such as relief valves, low-water cutoffs, and pressure controls. 9. Electrical Components: Inspect electrical components, wiring, and connections for wear, corrosion, or loose connections. Ensure the proper functioning of controls and safety interlocks. 10. Water Treatment: Check the condition of water treatment equipment and verify that water quality meets recommended standards to prevent scale and corrosion. 11. Expansion Tank: Inspect the expansion tank for proper pressure and condition. Ensure it is properly connected and functioning. 12. Gauges and Instruments: Calibrate and test pressure and temperature gauges. Check other instruments for accuracy and proper operation. 13. Insulation:Inspect the boiler insulation for any damage or deterioration. Proper insulation helps maintain energy efficiency. 14. Documentation: Review and update the boiler's logbook and inspection records. Ensure that all required documentation is up-to-date and accessible. |

It's essential to follow the manufacturer's guidelines and local regulations during the inspection process. Additionally, consider consulting with a qualified boiler inspector or technician for a comprehensive examination and adherence to safety standards. Regular inspections, combined with proactive maintenance, contribute to the safe and reliable operation of the boiler system.