For safety purposes, Jaytech recommends that all steam boilers be outfitted with some sort of stainless-steel injection system for your boiler chemicals. Depending on the number of chemicals in your treatment program, a simple quill may suffice.

Blog tagged as Boiler Water Systems

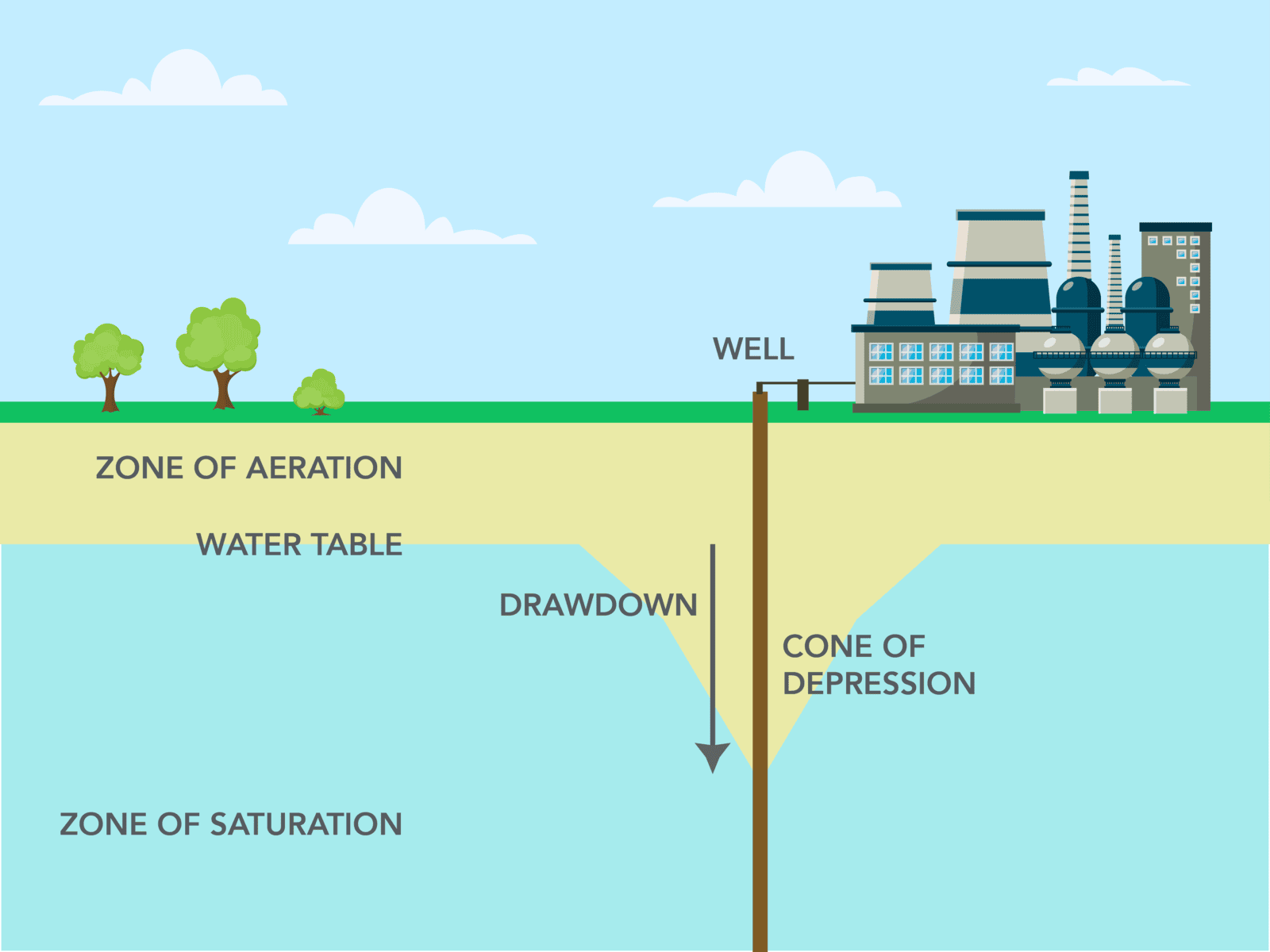

Minerals, metals, organics, dissolved gases, and suspended material are all present in makeup water to some degree. The specific type and quantity of contaminants in the makeup water will require the use of pretreatment and chemical additives in a system.

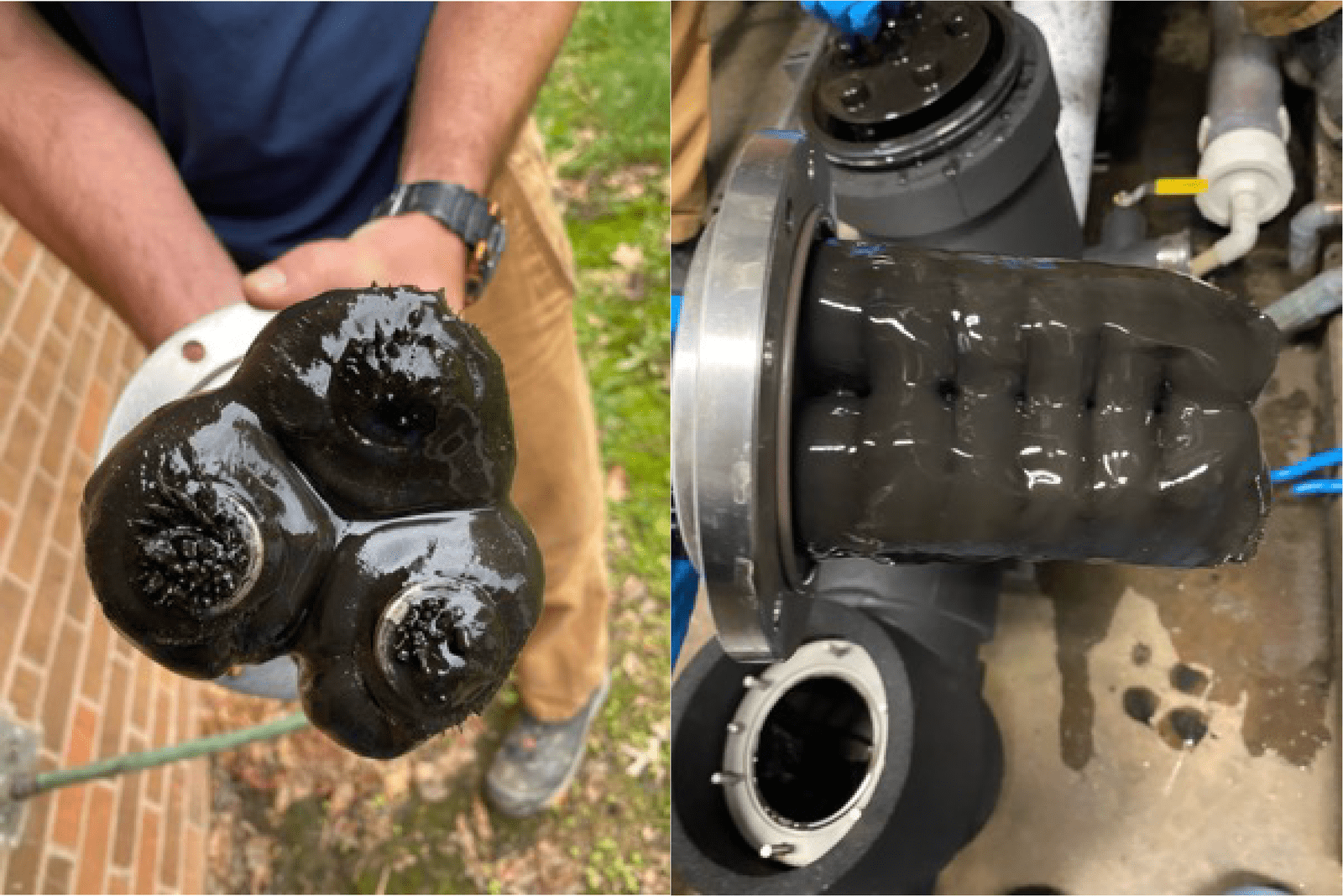

Performing a steam boiler inspection is crucial to ensure the safety, efficiency, and longevity of the system. Regular inspections help identify and address potential issues such as corrosion, leaks, and wear in critical components like the pressure vessel, burner assembly, and piping.

More accurate test results and safer sample retrieval with a simple Sample Cooler.

If you are looking for a filtration solution, Magnetic Filtration might be what you’re looking for. With a one time start up cost and reusable components, magnetic filtration is an easy win.

Learn the vital reasons behind the necessity of a condensate neutralizer. Protect your plumbing, environment, and comply with regulations.

Categories

Tags

- Sample

- Passivation

- Cooling Tower Water Treatment

- Safety

- Corrosion

- White Rust

- Closed Loop Water Treatment

- Efficiency

- Steam Boiler Water Treatment

- Steam Boiler System

- Steam Boiler

- Filtration

- Maintenance

- Conservation

- Air Handler

- Water Treatment

- Bacteria

- Savings

- Cleaner

- Coil

- Healthcare

- Chemical Program

- steam

- Layup

- LEED

- Remote Monitoring

- Automation

- Wireless

- Institutional

- Scale

- Condensation

- Condensate Neutralizer

- Boiler Water Systems

- Re

- Hot Water Boiler

- Pumps

- Glycol

- Hydronic Loop System

- Closed Loop Systems