Addressing Water Treatment Challenges: Jaytech's Customized Approach Delivers Remarkable Results for an Institutional Facility

Jaytech offered a second opinion and ultimately implemented a customized solution to effectively address the water treatment challenges faced by an institutional facility. Jaytech performed a comprehensive assessment of their existing water treatment program and diagnosed the issues facing their systems. Utilizing a strategy involving a mechanical and chemical approach, Jaytech successfully mitigated corrosion-related issues. As a result, the system's overall health significantly improved, accompanied by a notable enhancement in heat transfer efficiency and system clarity. These strategic measures taken by Jaytech are poised to extend the system's lifespan and reduce utility costs, ensuring optimal outcomes and utmost satisfaction for this new customer.

How did we get involved?

In February 2022, Jaytech connected with a school district seeking expert assistance in assessing the condition of their closed loop. Our experts were called in by a reputable mechanical contractor, installing new equipment for the facility. Jaytech promptly conducted an on-site visit to provide a thorough and comprehensive water treatment survey to gain an understanding of the system's current state.

What was the issue?

The preliminary findings of the on-site survey revealed a significant presence of corrosion within the closed loop system. The corrosion inhibitor level within the system was found to be below the recommended industry standards, which had led to significant corrosion and had also proven detrimental to its overall condition. Consequently, the system was experiencing or at risk of experiencing several adverse consequences, including efficiency loss, mechanical failures, compromised system integrity, and a reduced operational lifespan for the overall system. Additionally, the elevated pH levels have resulted in the byproducts of nitrates and ammonia ions, further accelerating corrosion, and exacerbating the pH imbalance. The high pH levels also adversely affect pump seals, potentially causing their premature failure. Moreover, the deficiency of yellow metal inhibitor, below industry standards, had contributed to the heightened copper corrosion observed in the system. Finally, Jaytech found iron corrosion byproducts, above industry standards, indicating a significant deterioration of the interior piping and the likelihood of ongoing material loss.

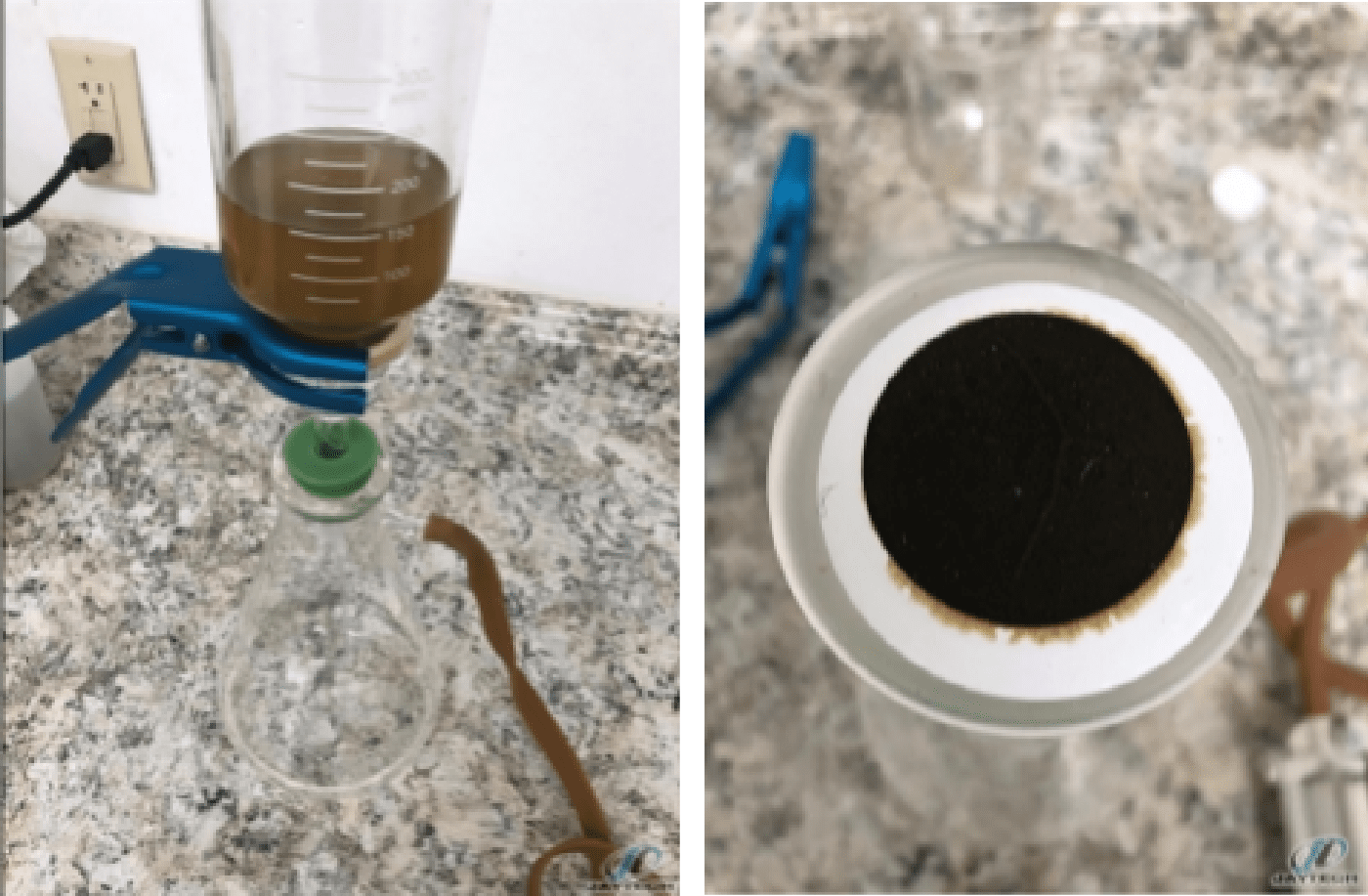

Above, a closer look at the preliminary results from a closed loop water sample testing.

How did we solve the issue?

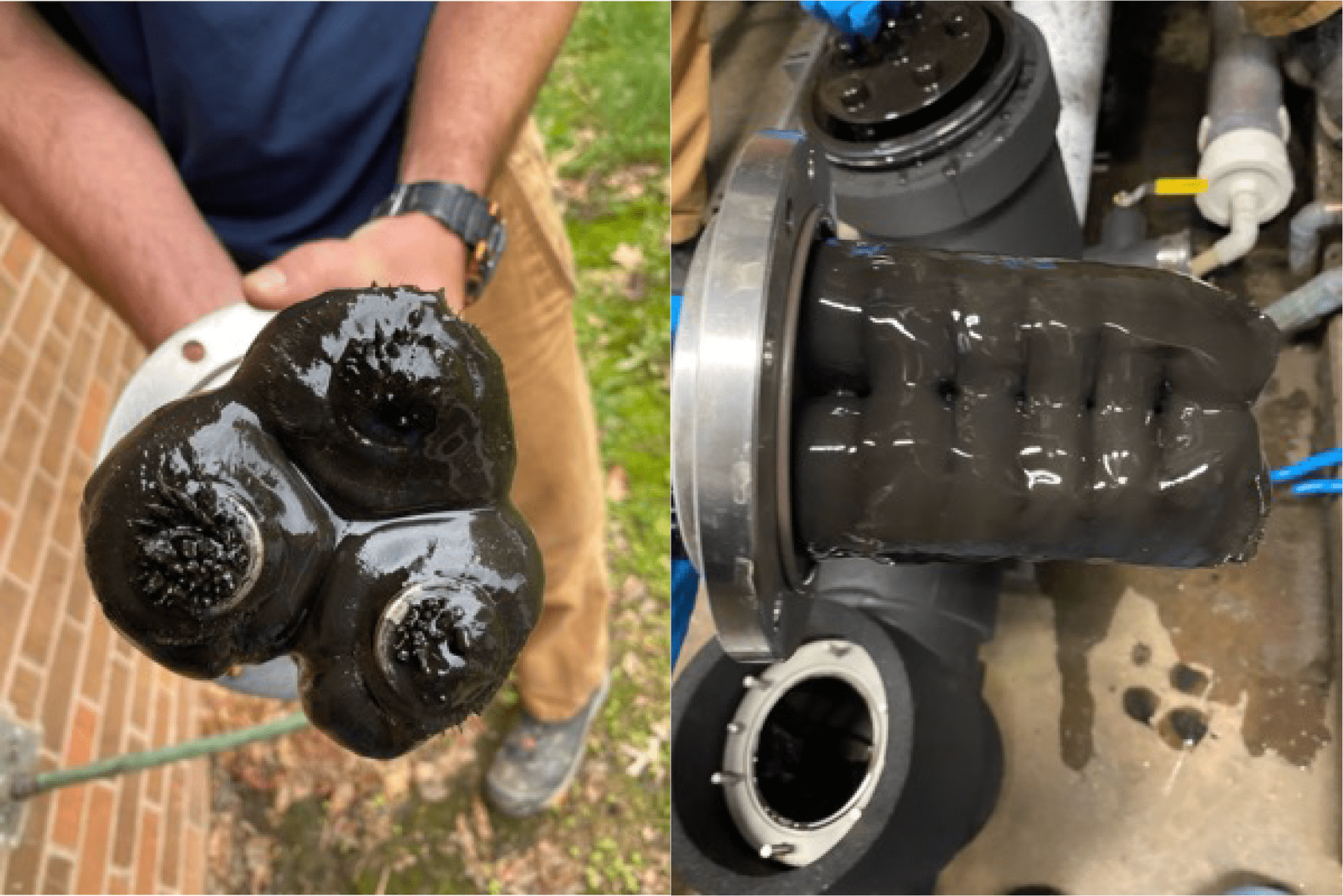

Jaytech was up to the challenge of tackling these issues and getting this system under control. Jaytech experts developed a customized chemical approach, aimed at optimizing the closed loop system's performance. This involved a meticulous cleaning process to effectively eliminate debris and contaminants, ensuring the availability of cleaner surfaces for the inhibitors to adhere to. Jaytech worked in close collaboration with a hired mechanical team and facilitated the installation of appropriate filtration mechanisms. Jaytech recommended that magnetic (see photo below) and cartridge filters be incorporated and upon completion, these measures expedited the system cleanup process and prioritized the conservation of the customers' consumables. Parallel to these efforts, Jaytech implemented a comprehensive water treatment program, specifically designed to safeguard the system against future corrosion-related issues, thereby ensuring its long-term integrity and functionality.

What did the customer appreciate about our services?

Jaytech demonstrated adaptability by promptly devising a solution that aligned with the customer's overall budget without compromising the expected outcomes for their systems. By implementing strategic changes, Jaytech significantly improved the system's performance, resulting in enhanced heat transfer efficiency and a notable reduction in overall equipment utilities consumption. Furthermore, with the system now operating optimally, the incorporation of a hydronic additive is scheduled to be introduced, aimed at generating additional utility savings for the facility, estimated at 10-15%. This proactive approach by Jaytech not only ensures the system's optimal functionality but also delivers tangible cost-saving benefits to the customer.

Above, two photos of the metallic debris pulled from this system with magnetic filtration implemented by Jaytech experts.