Uncovering the Indispensable Benefits of a Condensate Neutralizer

Why do I need a Condensate Neutralizer?

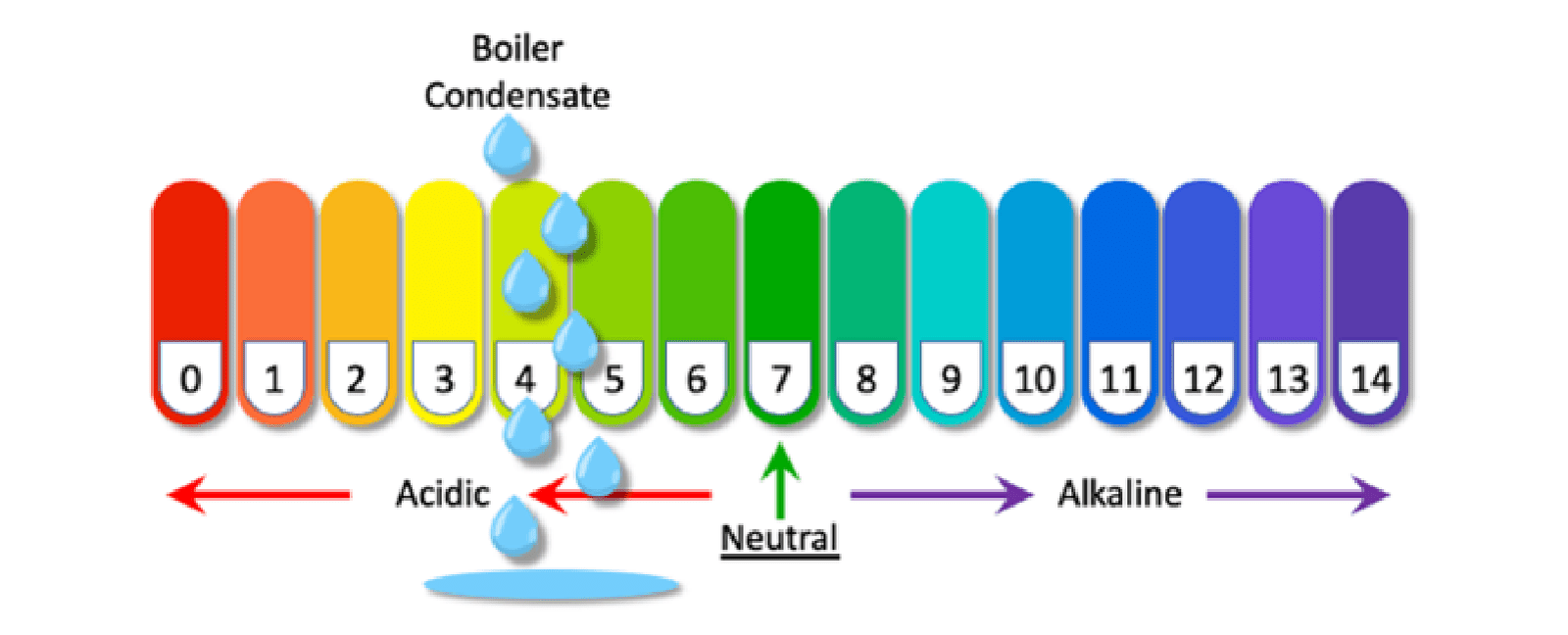

Your system is building up condensate inside the pipes. If the acidic condensate is not neutralized the low pH can lead to corroded pipes, expensive floor and drain repair, potential environmental hazards, health risks, and possible compliance issues.

What is a Condensate Neutralizer?

The material is typically in the form of pellets, granules, or blocks and is placed in a tank or chamber through which the condensate flows through prior to the drain or reuse as effluent.

What systems need a Condensate Neutralizer?

Condensate neutralizing material is a substance used to raise the pH level of acidic condensate produced by condensing appliances such as boilers, furnaces, and water heaters.

How do I set up a Condensate Neutralizer?

- Determine the chamber location: Choose a suitable location for the condensate neutralization chamber. It should be easily accessible for maintenance and close to the condensing appliance drain line.

- Select the chamber: Purchase a condensate neutralization chamber that is appropriate for your application (correct MBH rating). Chambers come in different sizes and configurations, so make sure to select one that matches the flow rate and volume of condensate produced by your appliance.

- Prepare the plumbing connections: Install a tee fitting in the drain line of the condensing appliance. The tee should have an outlet for the condensate line and another outlet for the neutralized condensate line that will connect to the chamber.

- Install the chamber: Position the chamber at the desired location, ensuring it is level and stable. Connect the condensate line from the tee fitting to the inlet of the chamber. Use the appropriate fittings, such as PVC or CPVC connectors, to make secure connections.

- Add the neutralizing material: Follow the manufacturer's instructions to determine the amount and type of condensate neutralizing material required for the chamber. Typically, the neutralizing material comes in the form of pellets or granules. Pour the material into the chamber, filling it to the recommended level.

- Connect the outlet: Connect the outlet of the chamber to the drainage system, ensuring a proper connection that complies with local plumbing codes. It is important to ensure that the neutralized condensate can flow freely into the drainage system without any obstructions.

- Test the system: After installation, run the condensing appliance and observe the flow of condensate through the chamber. Check for any leaks or issues with the connections. Also, monitor the pH level of the neutralized condensate periodically to ensure that the chamber is effectively neutralizing the acidity.

- Protection against corrosion: Acidic condensate can corrode plumbing pipes, drains, and fixtures over time. By neutralizing the condensate before it enters the drainage system, you protect your plumbing infrastructure from damage, extending its lifespan and reducing the need for costly repairs or replacements.

- Environmental compliance: Many environmental regulations require the neutralization of acidic condensate to protect the environment. By adhering to these regulations, you help prevent the discharge of harmful substances into the wastewater system, minimizing the impact on water bodies, aquatic life, and ecosystems.

- Improved indoor air quality: Un-neutralized acidic condensate may emit fumes or odors that can be unpleasant or potentially harmful when released into living spaces or areas where people are present. Properly neutralizing the condensate helps maintain better indoor air quality and creates a safer and more comfortable environment for occupants.

- Maintenance and efficiency: A properly functioning condensate neutralization chamber ensures that the condensing appliance operates efficiently and maintains its performance over time. By preventing the buildup of corrosive elements in the drainage system, you minimize the risk of clogs, blockages, and system malfunctions, which can lead to reduced efficiency or breakdowns.

- Compliance and legal considerations: Installing a condensate neutralization chamber and following local building codes and regulations demonstrates your compliance with environmental and safety standards. This helps you avoid penalties, fines, or legal issues that could arise from non-compliance.

- Corrosion: Acidic condensate from condensing appliances, such as boilers or water heaters, can corrode pipes, drains, and fixtures over time. This corrosion can lead to leaks, blockages, and costly repairs or replacements of plumbing infrastructure.

- Environmental hazards: The discharge of unneutralized acidic condensate into the wastewater system can harm the environment. The low pH levels can negatively impact water bodies, aquatic life, and ecosystems. This can result in non-compliance with environmental regulations and potential legal consequences.

- Health risks: Unneutralized condensate may emit fumes or odors that can be unpleasant or potentially harmful when released into living spaces or areas where people are present. These fumes can affect indoor air quality and pose health risks to occupants.

- Compliance issues: Many building codes and environmental regulations require the neutralization of acidic condensate before it enters the drainage system. Failing to comply with these regulations can result in penalties, fines, or legal issues.

- Reduced efficiency and system malfunctions: Without a condensate neutralizer, corrosive elements can accumulate in the drainage system, leading to clogs, blockages, and malfunctions in the condensing appliance. This can reduce the efficiency of the system, increase energy consumption, and potentially cause breakdowns.

What are the benefits of a Condensate Neutralizer?

What can go wrong if I don’t have a Condensate Neutralizer?

If you don't have a condensate neutralizer, several issues can arise:

Overall, not having a condensate neutralizer can result in damage to your plumbing, environmental harm, health concerns, compliance issues, and decreased system efficiency. Installing a condensate neutralizer is essential to mitigate these risks and ensure the proper functioning and longevity of your plumbing system.

Why should I trust Jaytech with my applications that require a Condensate Neutralizer?

For over 45 years Jaytech has been a leader in our industry. We have been consulting on water treatment plans to help our customers realize efficiency and longevity in their water systems. We have commissioned and recovered hundreds of systems during that time.

Jaytech is on the cutting edge of innovation in water treatment. Our wide variety of product offerings lends itself to giving our customers a personalized custom water treatment plan like no other water treatment company can. We have created customizable blends of traditional chemicals, ultra concentrates, and solid chemistries. Coupled with our line of complimentary products and our local hands-on approach, Jaytech has earned a reputation as a trusted partner in water treatment.

Jaytech leads the water treatment industry with CWTs, the most highly qualified education for water treatment. There is no one more qualified to design a water treatment plan for you.

1. 45-year track record.

2. Extensive customizable water treatment chemicals and complimentary products.

3. Jaytech offers more CWT specially qualified Reps.

For more steam boiler maintenance and efficiency articles, try filtering our blog articles by "Steam Boiler Water Treatment," or click the button below.