Taking Care Of The New Water Entering Your System

What is Makeup Water?

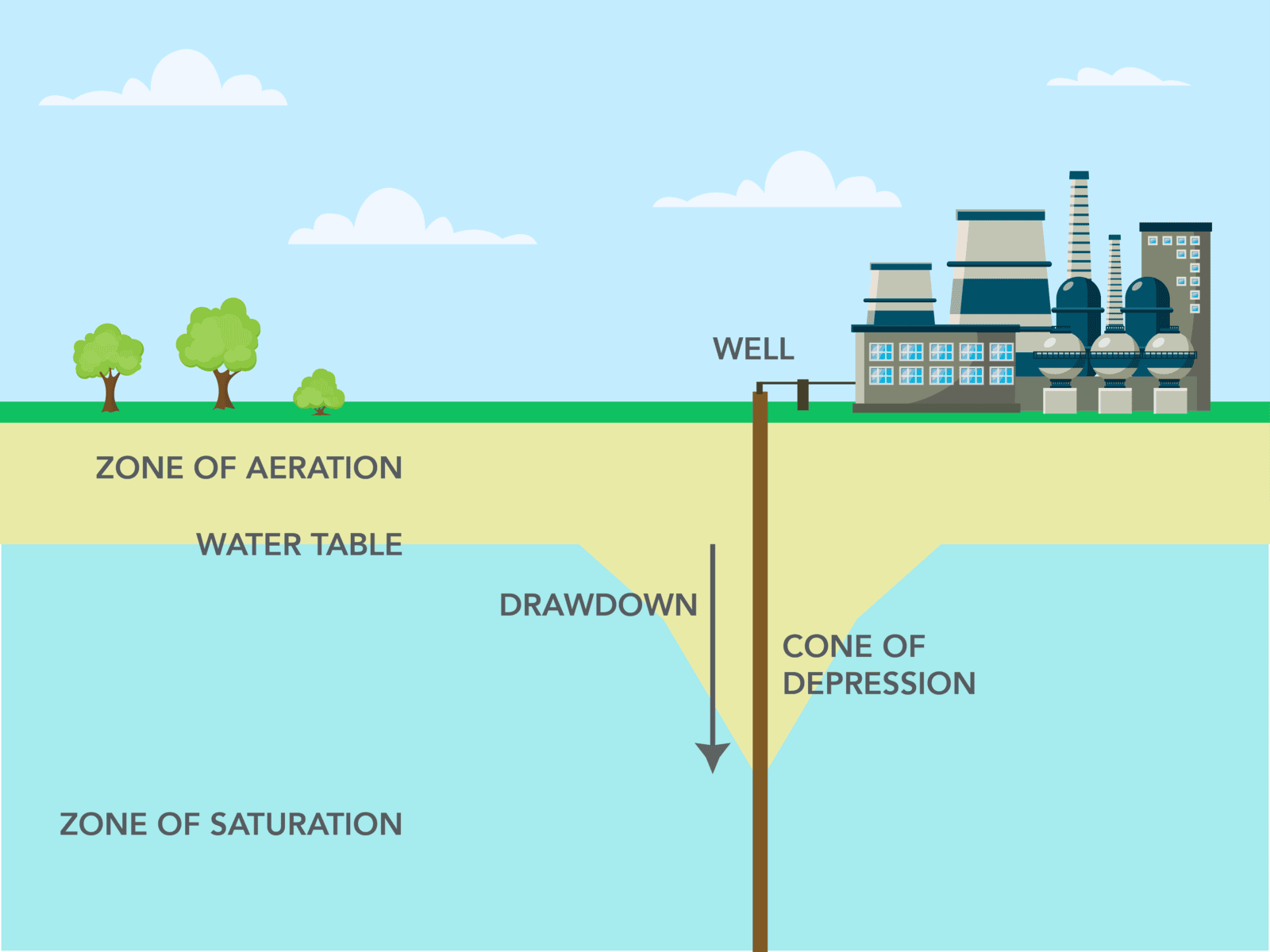

Heat transfer systems, such as steam boilers and cooling towers, bleed water to control the quality of the water contained in the system. These losses must be replaced by fresh water entering the system. This replacement water is termed “make up.”

What is important to know about your Makeup Water?

Water is never completely free of contaminants. Water is known as the “universal solvent.” Minerals, metals, organics, dissolved gases, and suspended material are all present in makeup water to some degree. Even the temperature of the incoming makeup water can have a drastic effect on its properties. The specific type and quantity of contaminants in the makeup water will require the use of pretreatment and chemical additives in a system.

Above: An RO System is one type of pretreatment used to remove contaminants from makeup water.

How is the quality of Makeup Water Controlled?

Your water treatment expert can solve any issues with makeup water quality. The water treatment industry has developed many technologies for modifying the quality of makeup water before it is introduced into a system.

- As an example for steam boilers, a very common issue is hardness. Water softeners can be introduced to remove calcium and magnesium.

- Steam boilers are also very sensitive to dissolved oxygen. A steam boiler’s system deaerator will mechanically remove oxygen. A water treatment expert will also feed an oxygen scavenger, such as sulfite, to remove the remaining oxygen.

There are dozens of equipment and chemical technologies available to improve water quality. Each technology is intended to tackle certain problems.

How does water quality affect your water treatment program?

A water treatment professional must know exactly what types of contaminants are in a system’s makeup water to deploy correct types and amounts of chemistries to preserve the integrity of a water treatment program.

Steam boilers, cooling towers and even closed loops are susceptible to the hazards of poor-quality makeup water. The water treatment industry has developed numerous chemical additives to mitigate the harmful effects of corrosion, scale accumulation, microbiological excursions, and remove suspended debris.

Who can help you determine the quality of your makeup water?

Often field water treatment professionals will carry a test kit which allows them to test for certain water parameters such as pH and hardness. While helpful, these field kits are extremely limited. A sample of the makeup water should be sent to a reputable, subjective laboratory, like Brothers Laboratory Services. A laboratory will provide a thorough analytical water panel of minerals, metals, and other contaminants in a system.

Why get your makeup water tested?

Brothers Laboratory Services can determine the amount and type of contaminants in your water and model their accumulation in heat transfer systems. This allows your field water treatment professional to determine what type and amount of chemicals to deploy and can also offer insight on settings for the tower and boiler. Taken together, this will allow your water treatment professional to optimize your water treatment program for the lowest amount of money.

Fast, Accurate, Easy

Our in house lab was built with your water treatment needs in mind. One more reason working with Jaytech is easy.