For safety purposes, Jaytech recommends that all steam boilers be outfitted with some sort of stainless-steel injection system for your boiler chemicals. Depending on the number of chemicals in your treatment program, a simple quill may suffice.

Blog tagged as Maintenance

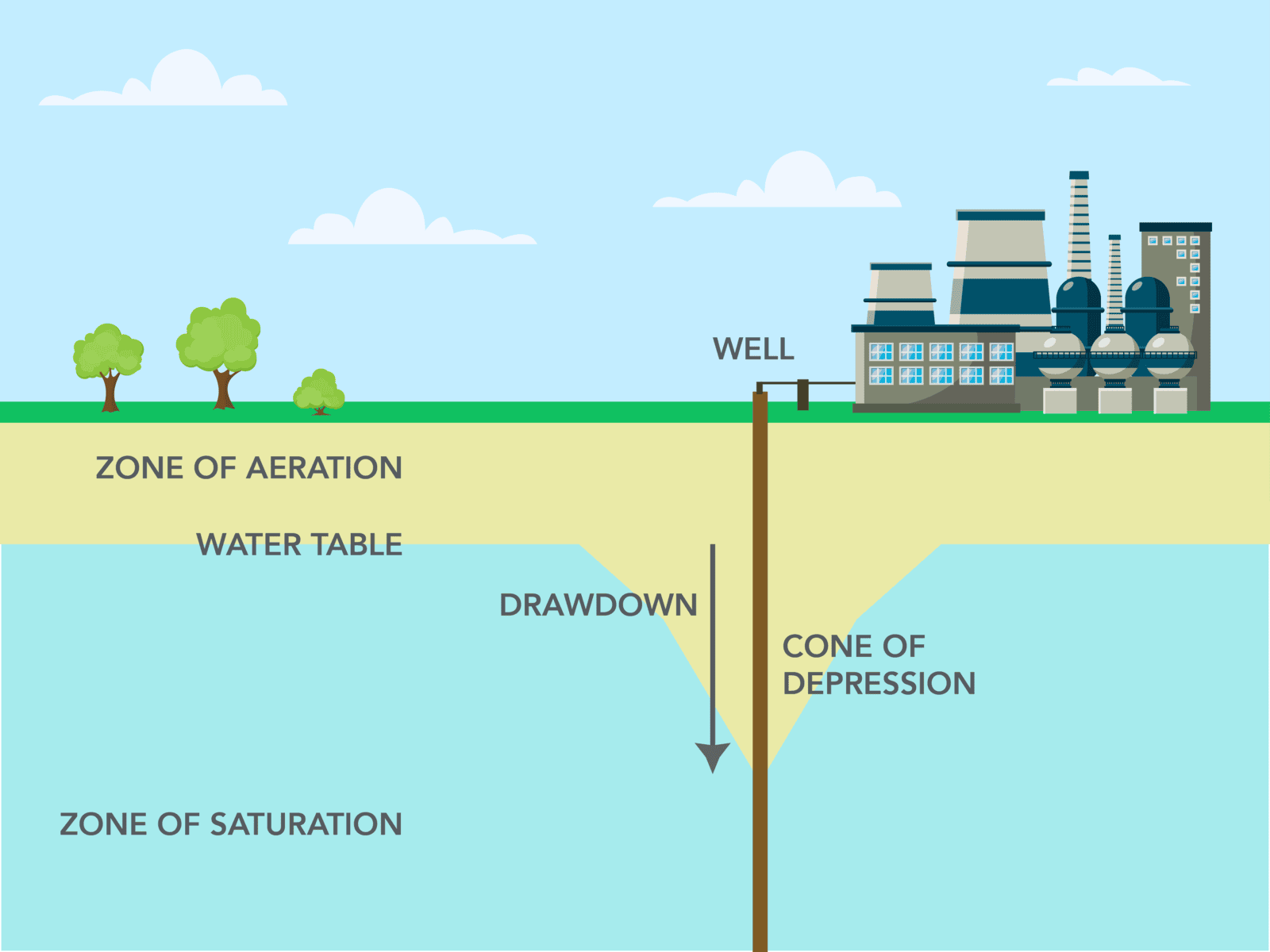

Minerals, metals, organics, dissolved gases, and suspended material are all present in makeup water to some degree. The specific type and quantity of contaminants in the makeup water will require the use of pretreatment and chemical additives in a system.

Performing a steam boiler inspection is crucial to ensure the safety, efficiency, and longevity of the system. Regular inspections help identify and address potential issues such as corrosion, leaks, and wear in critical components like the pressure vessel, burner assembly, and piping.

Our goal is to keep you up and running with reduced chemical degradation, and clogging.

More accurate test results and safer sample retrieval with a simple Sample Cooler.

Executing a proper layup procedure aimed at safeguarding cooling tower systems from scale formation, dissolved solids, and debris accumulation that can compromise operational integrity and longevity.

It’s that time of year, how are you laying up your system? Jaytech experts recommend two versions of a layup. Make sure your system is laid up correctly by working with an expert.

Is your cooling tower an important part of your business operations? Make sure you are getting maximum efficiency and longevity of system life with proper cooling tower water treatment and regular service.

Categories

Tags

- Sample

- Passivation

- Cooling Tower Water Treatment

- Safety

- Corrosion

- White Rust

- Closed Loop Water Treatment

- Efficiency

- Steam Boiler Water Treatment

- Steam Boiler System

- Steam Boiler

- Filtration

- Maintenance

- Conservation

- Air Handler

- Water Treatment

- Bacteria

- Savings

- Cleaner

- Coil

- Healthcare

- Chemical Program

- steam

- Layup

- LEED

- Remote Monitoring

- Automation

- Wireless

- Institutional

- Scale

- Condensation

- Condensate Neutralizer

- Boiler Water Systems

- Re

- Hot Water Boiler

- Pumps

- Glycol

- Hydronic Loop System

- Closed Loop Systems